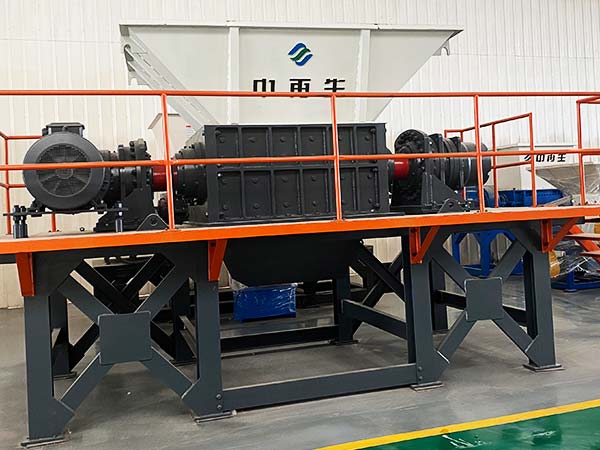

The DS46120 Dual-Shaft Shredder is engineered for high-capacity, efficient shredding of tough scrap metal and industrial waste. With its robust, dual-shaft design, this shredder provides optimal torque and cutting power, making it the ideal choice for handling large volumes of heavy scrap metal materials in recycling plants, scrap yards, and waste processing facilities.

Equipped with heavy-duty alloy steel blades, the DS46120 is built for durability and long-lasting performance, even under the most demanding conditions. The machine’s low-speed, high-torque shredding action minimises noise and dust, enhancing operational safety. Its intelligent control system ensures smooth operation by providing automatic overload protection and reverse functionality to prevent jams and extend the life of the equipment.

The DS46120 is perfect for processing a wide variety of metal and non-metal waste, from automotive scrap to metal containers, and its modular design ensures easy integration into existing recycling lines, reducing downtime and maintenance needs.