Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

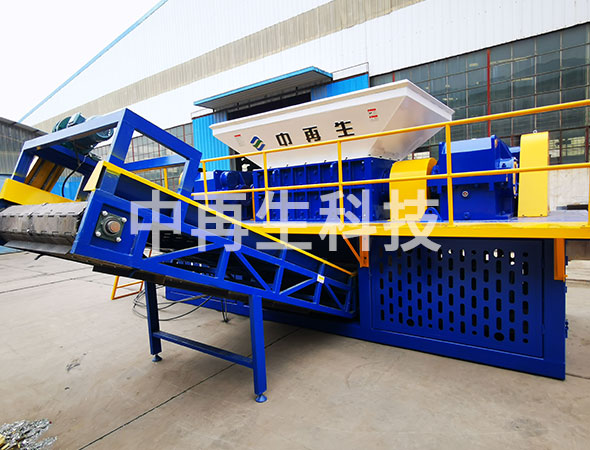

The DS46150 series double axis shredder is welded from thick steel plates and serves to support and fix components such as the crushing head, screen mesh, and motor. Made of alloy steel, it has high strength and wear resistance. There is a certain gap on the crushing head, which can subject the metal object to shear and tension during the crushing process.

Made with sieves of different pore sizes, it plays a role in controlling the size of the metal object after crushing. Selecting high-performance motors can provide sufficient power to drive the crushing head to work. The working principle of a metal shredder is mainly to use the crushing head to exert forces such as impact, shear, and tension on metal objects, causing them to be crushed into small pieces or powders.

The metal shredder has the characteristics of high torque and low-speed rotation, which can effectively crush large or long metal objects, and can process hundreds of kilograms to several tons of metal objects per hour.

The tool is made of imported alloy steel, with high wear resistance and moderate toughness. It is processed by high-precision machine tools, with significantly improved mechanical properties and greatly extended service life. The tool can be repaired by surfacing for many times to save the use cost and prolong the service life.

Dual three-phase asynchronous motor + dual planetary reducer drive and hydraulic motor drive are available. The motor + reducer is connected by German standard spline, with stable torque transmission, high precision and good guidance, giving the equipment strong power; Hydraulic drive, stepless speed change, strong material adaptability.

| Model | Power(kW) | Grinding chamber dimension(mm) | Total Weight(t) | Size(mm) |

| DS46100 | 55+55/6 | 1090X1080 | 8 | 5400X2000X2730 |

| DS46120 | 75+75/6 | 1210X1080 | 17.5 | 5520X2000X2730 |

| DS46150 | 90+90/6 | 1570X1080 | 18 | 5880X2000X2730 |

| DS46180 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

| DS46200 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

Solution